Girder Gantry Cranes Ensure Precision Handling!

WE ARE YOUR SOLUTION

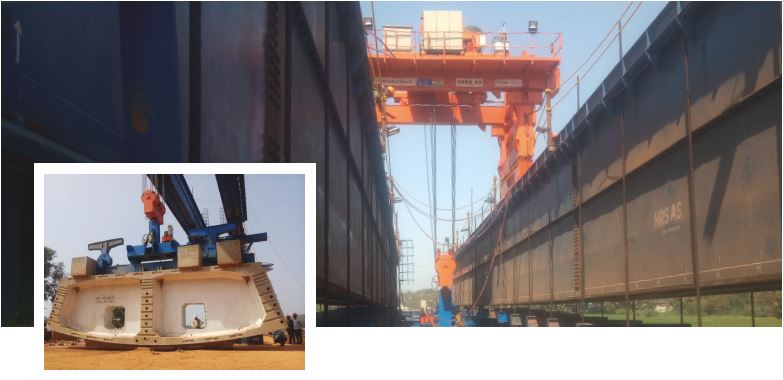

Launching girder gantry cranes with span adjustment, motorised hook and hydraulic CT supplied for the construction of India’s third longest cable-stayed bridge.

About the project

The Zuari cable-stayed bridge is a part of a 12-km-long road project, which links Panaji and Madgaon in Goa. The 1225m-long bridge, built over the Zuari River, is the third longest cable-stayed bridge in India and connects North Goa and South Goa.

The project was undertaken by one of the largest construction and infrastructure majors in India. Such projects are generally carried out using large precast segments and require the use of advanced machinery for construction.

About NRS Bridge Construction India Pvt. Ltd.

NRS Bridge Construction India Pvt. Ltd. is a subsidiary of NRS AS, Norway. Established in 1983, NRS AS is the world leader in supplying highly specialised and advanced construction equipment for bridges. Its services range from the design and supply of specialised bridge building equipment such as Form Travellers and Movable Scaffolding Systems for cast-in-situ bridges (for balanced cantilever and full span), to the much larger scale full span precast method. NRS also offers services for technical assistance and construction management on site, which cover associated assembly, commissioning, operation and maintenance of the equipment.

In the year 2016, the company was engaged for supplying the bridge building equipment for the construction of the Zuari Bridge. It has supplied Launching Girders and allied equipment for constructing the bridge.

Handling challenges

For this project, NRS was looking for Launching Girder Gantry Cranes capable of ensuring precision handling and offering the highest safety and reliability.

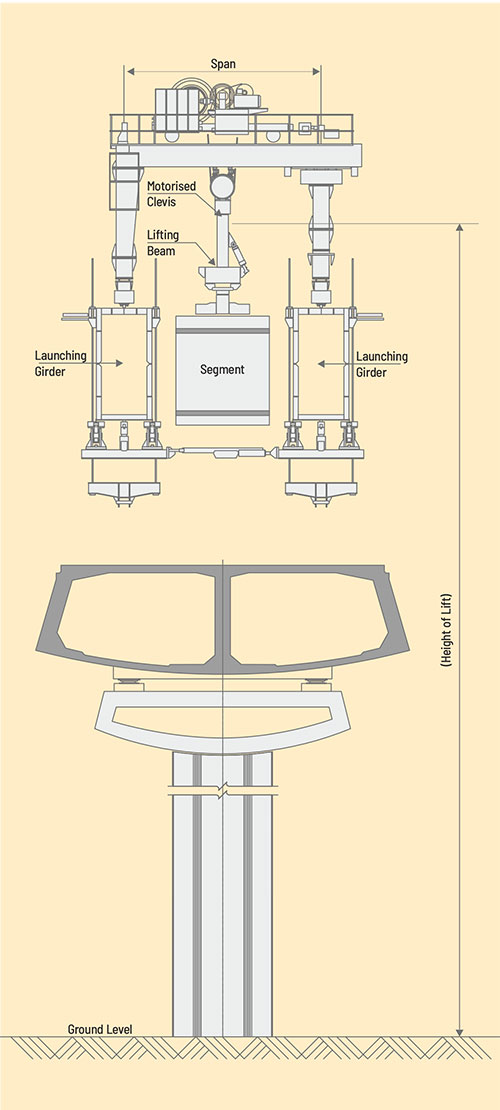

The cranes mounted atop launching girders were required for lifting precast segments weighing approx. 80t over a height of about 30m and placing them precisely on the precast girders. To ensure precision and jerk-free handling of segments, additional features such as a motorised hook that could rotate through 360° and advanced hydraulics for cross traverse were required. The bridge has a few smaller radius curves and thus, its width is not uniform across the entire length and hence, a provision for adjusting the span of the cranes was essential. The NRS team was also very particular about providing various safety features to take care of the gradient, load swing, etc. Considering that the project was being executed on the western coast of India where heavy winds and storms are prevalent, it was essential to ensure good protection that could help the equipment withstand high speed wind.

All such requirements certainly needed expertise and a unique approach to design while engineering these cranes.

Solution from ElectroMech

Taking into consideration the requirements of NRS, the ElectroMech team developed a highly customised solution built around our gantry crane. Our experience of designing solutions for over a thousand challenging infrastructure projects including the Signature Bridge, the Gangapath Bridge and the Mandovi Bridge came in handy. Earlier, we had supplied 3 nos. of gantry cranes of 100t to the main EPC company for the same project, which further reinforced the trust in our capability while being awarding the contract.

span and 30m height of lift (HOL) and supplied two identical cranes for the project. Features like span adjustment, motorised hook, hydraulic cross traverse (CT) for precise motion, emergency brakes and automated storm anchors were incorporated in both the cranes.

Features of the crane solution offered by ElectroMech

- Span adjustment - The cranes are mounted on the launching girders which are set according to the width of the launching girder. On a curved path, sometimes this area may get slightly reduced and hence, the crane span also needs to be manoeuvred accordingly. A special slew bearing mechanism fitted in between the legs and the end carriages allows easy span adjustment by +/-250mm.

- Working the gradient - The cranes are designed to overcome the gradient arising due to natural elevation. All the motors on both the cranes are designed such that the cranes could operate even on a longitudinal gradient of 4% (along the LT) and a transverse gradient of 0.5% (along the CT).

- Motorised hook - The precast segment lifted using the clevis has to be rotated to pass from the gap between the launching girders. With the slew bearing mechanism, the segment could be rotated through 360° in the clockwise and anti-clockwise directions to easily pass through the gaps between the girders.

- Hydraulic CT - A hydraulic mechanism was adopted which could position the segments with micro adjustment. The desired cross travel stroke of 800mm was achieved with hydraulic mechanism that also ensured jerk-free placement of precast segments.

- Emergency brake - An emergency brake was fitted on the wire rope drum. It offers additional safety, apart from the load limiters and standard brakes. The special calliper brake actuates and holds the load intact in case of primary brake failure.

- Automated rail clamps - Manual storm anchors are standard offerings from ElectroMech. However, for additional safety, automated rail clamps were provided to avoid toppling of the crane during adverse weather conditions. These rail clamps (anchors) are also used for parking the crane safely at any location during routine operations.

How NRS benefitted from ElectroMech solution

By procuring cranes from ElectroMech, NRS experienced several benefits such as:

- Highly reliable crane technology, which competently addressed their exacting demands.

- Superior quality – Our cranes are manufactured in a world-class manufacturing plant.

- Quick deliveries – Our experienced design team could develop an appropriate solution without any iterations and a large manufacturing capacity made it possible to engineer cranes within 100 days.

- Benchmark service support – Like all our other crane installations, these cranes are backed by excellent after-sales service support from our service subsidiary – Cranedge. This avoided any downtime on the project site and ensured completely safe operations through periodic checks.

Total number of cranes: 2

| Type | SWL | Span | Height Of Lift |

|---|---|---|---|

| DG Gantry Cranes | 100t | 5.35m +/- 250mm adjustment |

30.00m 26m below launching girder and 4m above launching girder |

Challenges

- Crane design with span adjustment

- Rotating precast segment without physical push / pull

- Precision in segment positioning

- Crane design to suit extreme weather conditions

Solution

- Easily adjustable span by +/- 250mm with specially designed crane legs with slew bearings

- Motorised hook for rotating the segments without manual intervention

- Hydraulically controlled cross traverse motion for jerk-free handling and precise positioning with +/- 800 mm traverse

- Safety features such as crane anchors, additional calliper brakes and automatic rail clamps for auto-clamping

- Storm anchors for safe parking and to avoid toppling of the crane